Heat Press Time And Temperature Chart – Guide 2023

Heat press machines are the best way to print any design on a shirt, mat, pad, or tile and keep it looking professional. You would be amazed at the finesse of the end product.

The main advantage of using heat press machines is their ability to help you in mass printing. You can use heat transfer vinyl to print a massive number of items in a short period.

Well, everything comes with cons, and so does the heat press machine. Under certain circumstances, you might have a bad experience because of a design flaw, printing difficulty, wrong size, slow speed, quality issues, reliability, etc.

The typical problems are when the design doesn’t come off well and quickly or fails to stick to the substrate’s surface. But, the question is WHY? One of the many reasons is malpractice and mishandling. For instance, the temperature was set extraordinarily high or low, the timer was not placed for the right time duration, or the pressure was not stabilized.

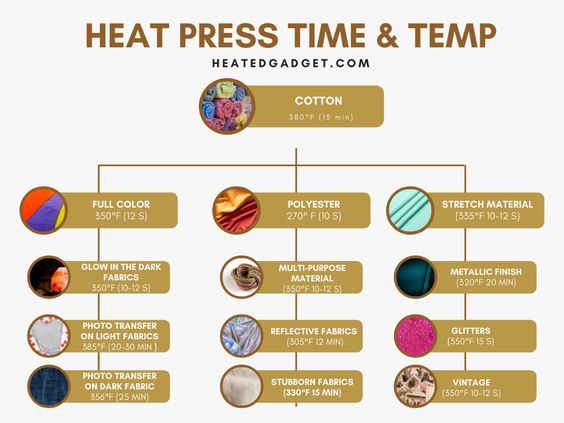

It would help if you remembered, “every garment tends to have different settings and thresholds for temperature and time.”

For your ease, we are enlisting suitable temperatures for the most commonly used fabrics.

Heat Press Time and Temperature Chart

| Full Color | 350°F | 12 s |

| Glow in the Dark Fabrics | 350°F | 10-12 s |

| Photo Transfer on Light Fabrics | 385°F | 20-30 minutes |

| Photo Transfer on Dark Fabrics | 356°F | 25 minutes |

| Cotton | 380°F | 15 minutes |

| Polyester | 270° F | 10 s |

| Stretch Material | 335°F | 10-12 s |

| Multi-Purpose Material | 350°F | 10-12 s |

| Metallic Finish | 320°F | 20 minutes |

| Reflective Fabrics | 305°F | 12 minutes |

| Stubborn Fabrics | 330°F | 15 minutes |

| High-Quality Digital Prints | 305°F | 5 minutes |

| Glitters | 350°F | 15 s |

| Vintage | 350°F | 10-12 s |

Ways for Setting the Time and Temperature for a Heat Press Machine

To run the heat press machine successfully, you must know the essential functions, especially when it comes to time and temperature. Usually, every machine comes with an appropriately detailed guidebook that helps you understand the functioning and operations depending upon the printing methods.

Here is a brief explanation of heat, temperature, and time settings:

Time setting

Typically, the perfect temperature is set by either a digital time display or a traditional dial. For time setting on a digital display, all you need to do is press the “up” or “down” arrow keys mentioned earlier. In a traditional dial, you turn the knob to set the time you want.

As far as time is concerned, timers are infused that add a self-off feature. It switches off the engine when the time circle is completed. Some timers have audible beep alarms too.

Heat/Temperature setting

Similar to time, the heat or temperature can be set. But, instead of seconds and minutes, the dial comes with either Celsius or Fahrenheit degree signs. We can say it works just like the heat setting of the microwave.

Best heat press machines for beginners

Heat Press Time and Temperature Guide

Whenever we talk about the quality and clarity of the print, multiple factors can be impactful such as correct time, pressure, and temperature. These settings must be kept appropriate if you want to transfer the graphics keenly, sharply, and hassle-free. But always consider the type of material you are working with.

Apart from the fiber difference, dark- and light-colored fabrics also vary. Light-colored fabrics work well at lower temperatures, but darker fabrics give better results at higher temperatures. Most people neglect that an untidy shirt with creases, wrinkles, oil stains, and dirt can hinder the printing process and ruin the quality. It would be preferable if you always wore a clean, ironed shirt.

List of best printers for transfer paper

1) Polyester or Sublimated Fabric

For polyester, you need lower temperature settings because of the delicate fabrics it has. All that is required for printing is a moderate amount of heat without leaving the heat press machine on the material for extended periods of time. The ideal temperature is 270°F, which must be applied for no more than 10 seconds. Always peel the transfer when the garment is still hot.

2) For Vinyl

Are you looking for the most feasible and pocket-friendly item to begin with a heat press machine? You should try quality heat transfer Vinyl.

In comparison to Polyester, Vinyl needs a bit higher temperature. The recommended temperature is 320°F, accompanied by a firm pressure that should be applied for a maximum of 15 seconds.

It will be enough to help you get a vibrant, clear, and quality design. Try preheating the Vinyl for a better print and heat transfer process. Here are the best vinyl heat press machines.

3) Cotton

Shirts are generally made with a variety of cotton. Cotton materials can withstand the test of time, use, and heat. Moreover, cotton is a durable material that has an ideal temperature of 380 °F. The time duration is the longest, which is 15 minutes. Always peel it off when it is hot.

Keep in mind that cotton also comes in poly blends too.

4) Stretch Material

Working with stretch materials like cover sheets is always a challenging task. Its handling can get tricky. Why? Because its printed graphic will expand or stretch and contract with the fabric’s stretching or shrinking, causing the print to look tattered.

Set the heat press machine at 335°F and apply it for 10-12 seconds. Before you remove the paper, let the print cool down.

5) Vintage

As the vintage reflects, it is a design that gives off a special faded pristine appearance. Considering a stylish trend to try, you must try it. There is a wide variety of vintage. For vintage looks, keep the temperature at 350°F and hold it for 10-12 seconds. Peel it off as long as the design is hot.

6) Full Color

This combination works best and offers full-color printing showing a perfect blend of shades and crisp contrast. The best temperature to use for printing full-color designs is 350°F that needs to be applied for as long as 12 seconds. Try peeling the design while it is hot.

7) Glitters

No one needs an introduction to what the glitters are. In short, it is used for producing a textured design that carries sparkles and shine. Glitter designs are equally tempting. The correct temperature is 350°F, and the adequate time duration is 15 seconds. Just like any other print, it has to be peeled off while the design is hot.

8) High-Quality Digital Prints

High-quality digital prints require extra care, especially when printing graphics by transferring the design to a special paper called “transfer paper” through digital means. Always set the temperature at 305°F and let it stay on the garment for about 5 minutes for a vivid transfer and quality. Remove the graphics when it is hot.

9) Reflective Fabrics

Usually used in safety gear, such garments come with a reflective surface. Choosing the right transfer paper is an essential step. 305°F is an ideal temperature, and 12 minutes is the appropriate time for printing. Once the design is cooled down, peel it off immediately to avoid scorch marks.

It is very sensitive to heat and requires a longer pressing time, so do it carefully.

10) Glow in the Dark Fabrics

One-of-a-kind fabric that illuminates in the dark is usually used in making children’s nightwear or crazy Halloween costumes. You should pick the right transfer paper for such material, setting the temperature at 350°F and time at 10-12 seconds. Before the print is cooled down, peel the design for dye migration.

11) Stubborn Fabrics

The type of fabric that makes your printing a challenging task with its stubbornness. It needs time, effort, efficiency, practice, and labor to get the design printed. Try using a temperature of 330°F and keep the time duration as maximum as 15 minutes. Peel the design when it is hot when dealing with stubborn fabric.

12) Metallic Finish

You can find a variety of fabrics that carry unique metallic finesse. For a crisp quality, set the temperature at 320°F for approx. Twenty minutes and let the print transfer. The peeling should be done when the design has been cooled down for these types of fabrics.

13) Photo Transfer on Light Fabrics and Photo Transfer on Dark Fabrics

The ideal temperature for photo transfer on light fabrics is 385°F, and for darker fabrics, less temperature range is required up to 356°F. The time duration is 20-30 minutes for lighter and a maximum of 25 minutes for lighter fabrics.

This type of htv will provide you with the perfect graphics and an impeccable finish. Once you have transferred the design, remove the design while it is still hot.

14) Multi-Purpose Material

With various uses, it has the requirement of 350°F temperature and 10-12 seconds in time. For multipurpose material, you will need a multipurpose machine too.

Best heat press for small businesses

Frequently Asked Questions

What temp do I set for my heat press for HTV?

For Vinyl heat press machine printing, the temperature must not be less than 300-degree F. Depending on the machine; it can go as high as 315°F or 325°F. For a striking and perfect design, 15 seconds will be enough at this temperature.

What is the best temperature for heat transfer paper?

Transfer paper works best at 350°F, but the temperature can be raised to 375°F. The temperature should never be lowered below 350°F, making it the lowest possible limit. In centigrade, the range is 177 to 191 °C. For the best result, let the 350°F work for 10–12 seconds.

What temperature should I heat press wood?

For heat-pressing wood, the temperature should be kept at 305 degrees. Some machines offer 320 degrees Fahrenheit as a suitable temperature. It will work like a pro if you use medium pressure and leave it for 15 seconds.

Why is my Vinyl not sticking?

- Pressing or ironing for too short a time

- Temperature set at inappropriate degree

- Pressure is not stabilized

What material can you use with a heat press?

Designs can be heat pressed or transferred onto both natural and synthetic fabrics. The best option is cotton, as it is durable. Polyester is one of the most sensitive fabrics that cannot withstand excessive heat. It can also be used for printing onto metals, mugs, ceramic tiles, plates, mousepads, glass, and even wood.

What temperature should my heat press be on for 100% Polyester?

For Polyester, you should set the temperature at 270 °F. Pressing Polyester should be done at low temperatures for about 10 seconds.

Can you put HTV on 100% Polyester?

Technically, the answer is no!

As Polyester is heat-sensitive, exposure to HTV can increase the risk of melting your polyester fabric.

Conclusion

We understand if you might find this heat press time and temperature chart and guide overwhelming. Nowadays, every machine comes with temperature and time recommendations. However, mostly these are difficult to understand.

But, with time, you will start learning about suitable temperatures and timer stings. Always keep in mind the basic principles of heat, time, and heat press methods. Everything will become easier for you.

Additional Questions

How can I determine the correct temperature for my heat press?

When setting the temperature for your heat press, the most critical factor to consider is the fabric you’re working with. Different fabrics tend to react differently to heat. For instance, 100 percent cotton is quite resilient and can withstand the highest temperature around 380 degrees Fahrenheit. On the other hand, fabrics like polyester are more sensitive, requiring a delicate temperature setting around 270 degrees Fahrenheit.

Most fabrics, however, fall in the mid-range and respond well to heat transfer temperatures between 315 and 350 degrees Fahrenheit. But remember, each heat press machine can vary. So, if you're unsure, it's always best to check the user manual of your specific heat press machine. Additionally, years of trial-and-error and getting a feel for different fabrics and heat press temperatures have served me well in mastering the art of heat pressing.

What is the optimal temperature and time to use for heat press transfer paper?

In my experience, when it comes to using heat press transfer paper, the best approach is to preheat your press machine to approximately 330°F or 165°C, with a medium-high pressure setting. Before applying the transfer, you’ll want to press your fabric for about 5 seconds just enough to smooth out any creases using the machine.

When that's done, peel the paper backing from your transfer and position your design on the fabric, with the printed image facing up. While it might seem mundane, these small details play a significant role in ensuring a clean, well-transferred image. Patience and precision are the keys that transformed my initial trial into a successful hobby.

What should be the temperature for heat pressing vinyl?

To successfully heat press vinyl, the key is to find a balance between applying adequate heat and avoiding damage to the vinyl. From my many vinyl heat pressing ventures, I’ve found that the ideal temperature range is between 260 ℉ to 315 ℉ (130 ℃ to 160 ℃), coupled with medium pressure. Working within this temperature range optimizes the adhesion process and ensures that your vinyl transfers perfectly without warping or distorting.

What is the typical duration for heat pressing a shirt?

When it comes to heat pressing a shirt, the process is pretty straightforward, although the length of time can vary depending on the color of the shirt. After adjusting your heat press to medium pressure and setting the temperature to 340-345°, the transfer time differs for dark and light shirts. Dark t-shirts typically require about 90 seconds, while light t-shirts take around 45 seconds for an optimum transfer.

By taking the time to use machines such as the Triton Heat Press, the Hotronix machine, or George Knight, you can fine-tune your heat pressing process, and before you know it, you'll be churning out professional-quality shirts. Remember, practice makes perfect!

I’ve been in the printing business for 25 years. I love to share my experiences and knowledge.