Heated bed: Why is it required for a 3D printer???

What is the heated bed?

A heated bed is a simple tool that can revolutionize the quality of the print. It works to prevent paper warping, which is the most common problem that can destroy print quality. It keeps the extruded plastic hot/warm and cools it down at an even rate.

Basically, it manages the cooling process of the materials used in 3D printing. If you want to eliminate printing issues such as poor adhesion or thermal runaway, heat beds can do wonders.

Usually, they are crafted based on the PCB heater layout, where the temperature is controlled through a thermistor. The typical optimum temperature of the heated beds is approx. 70 degrees. The preferable option is “metal heat beds” because they are designed to retain and spread the heat efficiently.

Buying a competent heat bed can make your prints go from chewy, warped, tacky-looking prints to neat and tidy, high-quality prints!

You can also get high-quality prints by using a good heat press machine.

Why is a heated bed required?

A quality heated bed is an additional component that will play an essential role in improving the 3D printer performance. But why is it so crucial for the printing industry? Well, here are the reasons:

- Warping, where the printed papers’ edges curl in different angles giving an untidy and stringy look, is a problem most people face. And, this problem can be solved easily with a premium quality heated bed, saving you effort, money, and time. It significantly reduces the chances of warping by heating the surface temperature so the print sticks.

- It is a valuable tool for removing the finished printed material from the surface without getting into any problems where prints get off or get scratched, ruining the quality.

- Heated beds help retain the temperature of the provided 3D printing space and let the printing materials give their best performance. It helps to slow down the cooling rate of the printed material reducing the temperature/heat stresses.

- For an adequate first-layer adhesion, you need a heated bed, as it decreases the risk of material sliding or slipping away. It lets the material stick to the optimal level.

Types of heated bed

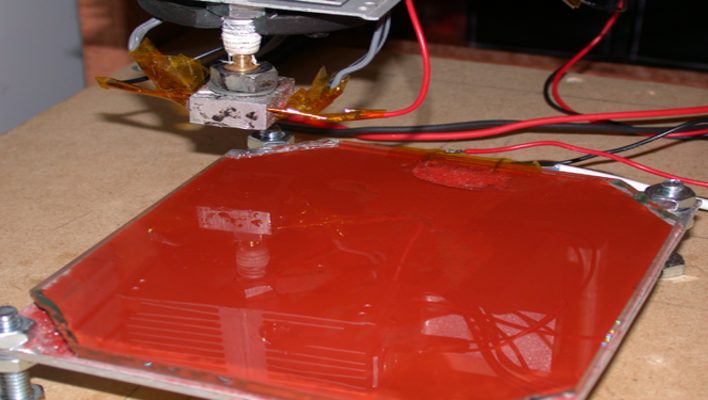

PCB HEAT BED

Using circuit boards or PCBs as the heating material delivers impressive performance and is comparatively affordable. It is the most common design and heating element used in making 3D printer heated beds.

Unfortunately, they are not suitable for 3D printers that are used frequently or for complex tasks. They must be installed in printers used for smaller projects as they comprise copper and aluminum strips.

These metals are prone to deformation at high temperatures. Another drawback is the longer time duration it needs to heat up. But once heated, it works brilliantly. The best PCB heat bed to buy is the “MK2A heat bed”.

ALUMINIUM CLAD HEATERS

Well, it might need a little bit of extra time to get installed either on a plate made of sturdy stainless steel or aluminum. In comparison to PCB, these might give you more advantages.

Being highly efficient and amazingly cheap, they ensure high-quality printing. Don’t forget to put the thermal paste to use by setting it between the clad heater and the surface to be heated.

POLYAMIDE FILM HEATER

Polyamide is famous as a valuable and usable tape of choice for pasting all over printing surfaces. Why? Because they are extremely heat resistant. It comes in a clean, smooth finesse. The biggest plus is its high adhesion for PLA.

To make a heater, all you need to do is sandwich a heating element between two thin films of polyamide. It is easy to use and install.

Consider it a reliable source that also heats up in no time. You can find it in various shapes and styles, all with an integrated thermistor.

Heated Beds Vs Filaments

ABS

Although ABS is less common in use because of its high tendency to warp, it is definitely more hard-wearing than PLA. It is slightly trickier to print as it demands much more heat or a higher temperature (around 90-100 degrees C) to work effectively.

To complement the temperature, keep the extruder at 230-240°C, and no adhesion problems will be faced. It is safe to use as a non-toxic material but keep in mind, it is not biodegradable.

Its variation called “ABS+” is proposed for creating high-quality, accurate 3D prints with a low tolerance range.

PLA

It is the most widely used type of filament due to its minimum ability to warp. That is why, if you are a beginner or have a home setup, you need to use PLA for 3D printing. Being the easiest to print with offers reliability and serves the purpose in a wide array of printing applications.

It is perfectly safe to use even when the kids are around. Other specs that make it’s a favorable choice are:

- Odorless

- Not requiring a heated bed

- Non-toxic

- Made from renewable resources

- Recyclable

PETG

We can say it offers the best of both worlds. PETG tends to possess all the printability factors of PLA, whereas it has the strength, toughness, and higher tendency to warp of ABS. It is usually treasured as a food-safe material, and that has amplified its use in industries. It is completely non-toxic as well as biodegradable. Like P- E -T, the G stands for the glycol, making the filament faster to heat up and effectively adhere.

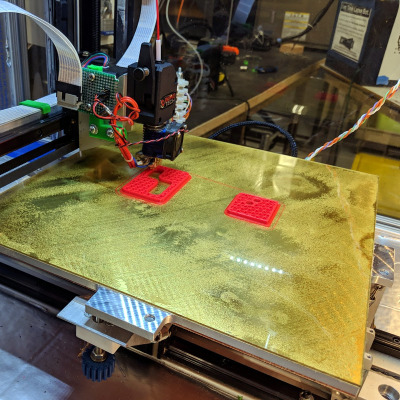

Heated bed 3d printer DIY

Are you looking for a quick guideline, easy steps, or a few nifty hacks to make your heated bed at home that tends to be more efficient and cheaper? You have come to the right place!

We will give you the way to make a heated bed that can heat up to 110° C in a matter of 6 minutes made with an aluminum plate and heated by isolated copper wire. You don’t need any extra tools.

- Form the heating wire with a bed of nails placed at equal distances on two sides and then stretch the copper wire in a regular pattern.

- Fix the wire distances with Kapton tape.

- Lift the wire from the bed of nails along with Kapton tape.

- Drill holes in the aluminum sheet will give you a plain and stable building platform. Fix the wire to the bottom of the platform with the Kapton tape.

- Uninsulate the wire ends to make a connection with the supply cable.

- Place the thermistor under the platform in the center.

- Time to check the heated wire for resistance just to make sure that you didn’t short-circuit it.

- Add a thermal cover with the silver side facing the aluminum and the gold side off the platform.

Top 9 printers for heat transfer paper

Additional Questions

Do you need a heated bed for 3D printer?

While not strictly necessary for all types of 3D printing, the addition of a heated bed can significantly broaden the range of materials you’re able to use with your 3D printer. With a zero degree surface, you can pretty much manage to print using PLA material. However, the addition of a heated bed can enhance the quality and precision of your PLA prints by reducing the incidences of warping. However, if you’re looking to venture into using ABS material, a heated bed is a must-have. Based on my experience in 3D printing, ABS material necessitates a heated print surface to produce quality prints.

What is the purpose of a heated bed?

A heated bed serves dual functions in 3D printing. Firstly, it boosts the surface energy of the print bed, thus enhancing the strength of bonding for the first layer. This is especially crucial when working with surfaces such as PEI or Kapton. Secondly, by maintaining the heat in the initial few millimeters of the print, a heated bed provides a solid, warp-free foundation for the remainder of the print. As someone who has spent a considerable amount of time in the world of 3D printing, I would say a heated bed can be a game-changer, reducing the risk of failed prints due to warping or poor adhesion.

Is it necessary to have a heated bed?

In 3D printing, a heated bed isn’t always a necessity, but it greatly depends on the type of material you’re using. If you’re working with PLA, a heated bed is nice to have but not mandatory. However, it does enhance the quality of the end result. On the other hand, if you’re printing with ABS, Nylon or other specific filaments, a heated bed becomes essential to counteract warping. In my experience, maintaining a heated bed becomes even more effective if combined with a heated chamber as it provides a consistent printing environment.

Can you 3D print on a cold bed?

Yes, you can 3D print on a cold bed, but it comes with its issues. The heart of the problem is when your bed is too cold, the base of your printed part cools and hardens before it completely lays flat. This rapid cooling can cause the print to warp and lose its adhesion to the bed, leading to print failure. In my printing journey, I’ve had a few disappointing end results due to such a scenario, so a well-regulated heated bed has become an integral part of my 3D printing setup.

I’ve been in the printing business for 25 years. I love to share my experiences and knowledge.