What is sublimation printing? Pros, cons, and Comparisons

Sublimation printing is an easy and cost-effective way to personalize products. It involves putting the design on a special type of paper called “sublimation transfer paper” and then putting it on polyester fabric or other materials with a polyester coating. It requires proper pressure and heat (350–400 degrees).

In layman’s terms, sublimation involves printing a design with sublimation dye and transferring it to a product with high heat.

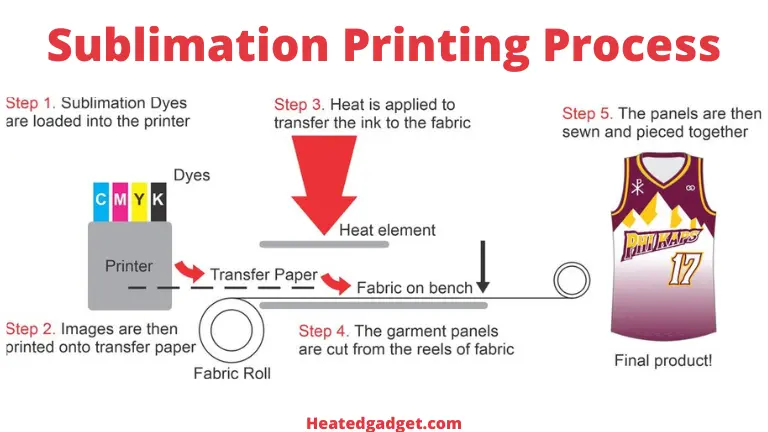

What Is the Sublimation Printing Process?

Heat is used in sublimation printing to fuse ink and cloth. To begin, a design is printed onto sublimation transfer paper. When heated, the inks transform into gas, which then combines with the fabric to print on it permanently.

What is needed for sublimation printing?

We need the following materials for sublimation printing:

- Design software

- Sublimation printer

- Sublimation blanks

- Sublimation ink

- Transfer paper

- Butcher paper

- Heat press machine

- Heat Transfer Application Tape or spray

- Heat-resistant gloves

Advantages of sublimation printing

- Your design will stay as long as the fabric does because the ink becomes part of the fabric.

- Traditional garment printing methods often result in stretched and blurred designs. Sublimation printing adds patterns to the entire garment at once, creating sharp and clear designs.

- Sublimation printing ensures that your designs will last through multiple washes without peeling, cracking, or fading.

- There is a very little learning curve.

- Sublimation allows printing on rigid surfaces like mugs and plates.

- You can try different color combinations without adding extra costs.

- It is easy and fast. You can fulfill hundreds of orders per day.

Disadvantages of sublimation printing

- The fabric should be 100% polyester or at least 75% polyester for best results in sublimation printing.

- If you want to use sublimation printing on items other than fabric, those items should have a polyester coating.

- You can sublimate the dark-colored surfaces.

- If you place the sublimated items under direct sunlight for longer periods, they can lose vibrance due to the effect of UV rays.

- You need to keep the printer on all the time. Otherwise, the printhead may clog.

- Sublimation printing is more expensive than other methods because it requires specialized printers and ink.

What Kind of Substrates Can I Sublimate?

Sublimation substrates can be made from any material with a dye-receiving coating. Metal, aluminum, fiberglass, ceramics, glass, plastic, and acrylic are examples of such materials.

All polyester items can be sublimated without this type of coating. However, you should always write down the recommended temperature and time for each substrate because some of them may be above the melting point of the material.

Difference between heat pressing and sublimation

Sublimation involves printing on transfer paper. When sublimation inks are heated, they turn into gases and become part of the surface they are on. Since the inks become part of the substrate, it results in durable transfers. This method only works with polyester and polyester-coated materials.

Heat pressing, on the other hand, is done by printing a design on transfer paper and then heating and putting pressure on the paper. The design transfers to the substrate. This method is suitable for polyester, cotton, and many other materials. The design is not long-lasting, though, because HTV adds a layer on top of the substrate as compared to sublimation, where the design becomes part of the fabric.

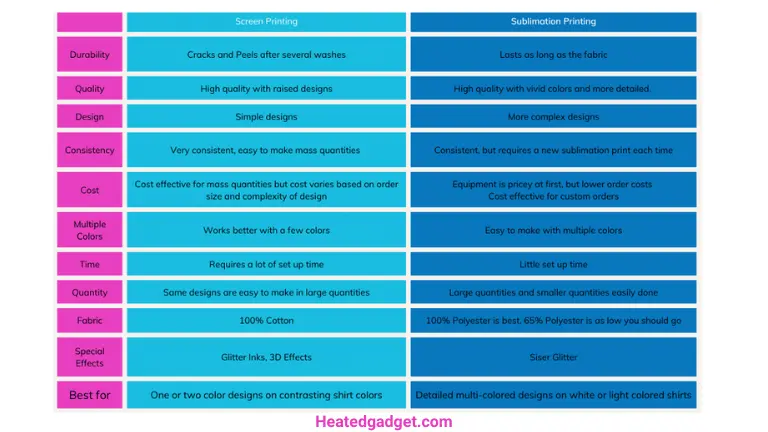

Sublimation vs screen printing

Screen printing is hard and has to be done by hand, while sublimation printing is easy and can be done automatically. In screen printing, you need to prepare a woven screen (a mesh stencil) for your design and then use a squeegee to transfer the ink to the fabric. It requires time and special lighting conditions.

Both provide vibrant designs. However, the screen prints might peel with time as the ink sits on top of the fabric.

Screen printing is best for bold designs that require fewer colors.

Sublimation supports only polyester, while screen printing can be done on cotton and cotton blends too.

Screen printing is best for bulk orders. But it costs a lot more than sublimation, which costs very little.

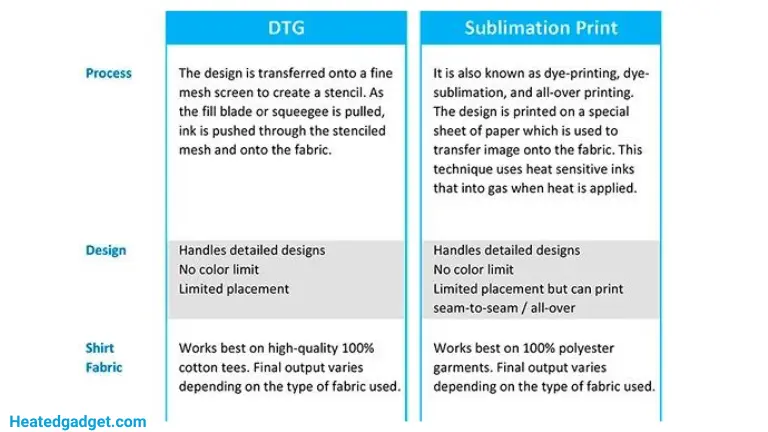

Direct to Garment (DTG) vs Sublimation

For DTG, the fabric or material needs to be treated first, and then the printer prints directly onto it. This holds the ink on top of the material very well. A similar, but much faster, way to cure the ink is to heat press it.

Sublimation works best with polyester fabric, while DTG printing works best with natural fibers like cotton, linen, canvas, and jeans. With DTG, prints look good on even dark materials.

A sublimation printer can cost between $1,000 and $10,000. You will also need a heat press, which costs $200–$2000, depending on your needs. Comparatively, a DTG printer can cost anywhere from $15,000 to $250,000 or more. DTG printers are a long-term investment that can help a business take advantage of a lot of different opportunities.

How is sublimation different than Cricut Infusible Ink?

Cricut Infusible Ink is essentially a form of sublimation. In contrast to vinyl, which sits on top of the fabric, the ink is infused directly into the fabric. The primary difference between the two is the respective equipment required.

You can either buy infusible ink sheets and use your Cricut machine to cut them out, or you can buy infusible ink markers and draw your design directly on the paper.

How much does sublimation printing cost?

A sublimation printer costs around $2000 on average. You can buy a decent heat press for $1500. Ink costs 15 cents per copy and the paper costs around 20 cents per sheet. Overall, you need at least $5000 if you want to start a small sublimation printing business.

Is sublimation ink toxic when heated?

No, sublimation ink is not toxic when heated. The fumes are completely safe as they are non-toxic and eco-friendly. However, you should make sure to buy good-quality sublimation ink.

What is the difference between a sublimation printer and a regular printer?

Compared to regular printers, sublimation printers use sublimation paper and dye-sublimation ink. Ink embeds itself into a medium like a shirt for a long-lasting, liquid-free print.

Can you use Cricut Design Space for sublimation?

Yes, Cricut Design Space works for sublimation projects. Design Space lets you make your sublimation designs if you’re not ready to buy Adobe Illustrator. Design Space is a great place to start designing for your dye sublimation business or for fun.

I’ve been in the printing business for 25 years. I love to share my experiences and knowledge.